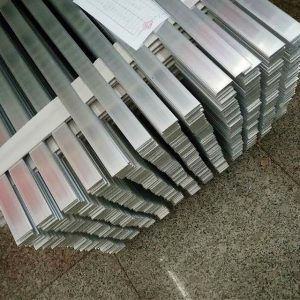

Aluminum Busbar

In electric power distribution, a busbar (also bus bar) is a metallic strip or bar, typically housed inside switchgear, panel boards, and busway enclosures for local high current power distribution. They are also used to connect high voltage equipment at electrical switchyards, and low voltage equipment in battery banks. They are generally uninsulated, and have sufficient stiffness to be supported in air by insulated pillars. These features allow sufficient cooling of the conductors, and the ability to tap in at various points without creating a new joint.

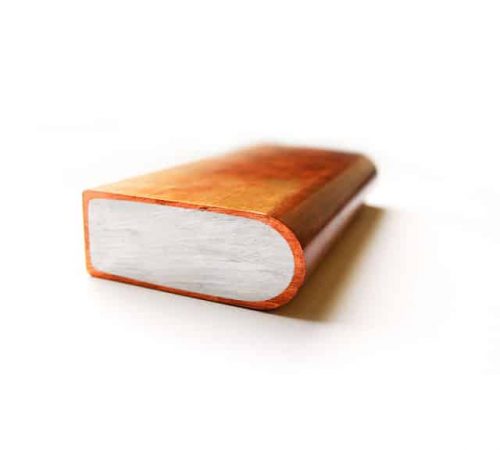

We YiKuo can supply Copper clad aluminum busbar, and Tin-plated aluminum busbar. It has ideal properties for lightness, cost-effectiveness, conductivity, corrosion-resistance and more. Copper clad aluminum busbar is also called copper clad aluminum busbar, copper clad aluminum busbar or copper aluminum composite busbar, etc. The cladding copper helps to increase the conductivity. By plating tin on the surface of copper clad aluminum busbar, it turns to Tin-plated aluminum busbar, and it helps to improve corrosion resistance.

Aluminum Busbar Application:

1) Busway, switchgear 2) Control cabinet 3) Transformer 4) Safety switch, vacuum switch 5) Relay system, rail power supply system, motor control center 6) Electrode correction coil, reactor and other windings 7) Railway traction equipment 8) High, medium and low voltage distribution cabinet, high and low voltage distribution cabinet conductive row 9) Generator sets and substations 10) High and low voltage busbars, busbars, touch-slip lines 11) Various copper and aluminum transition joints

look more about our B2B website