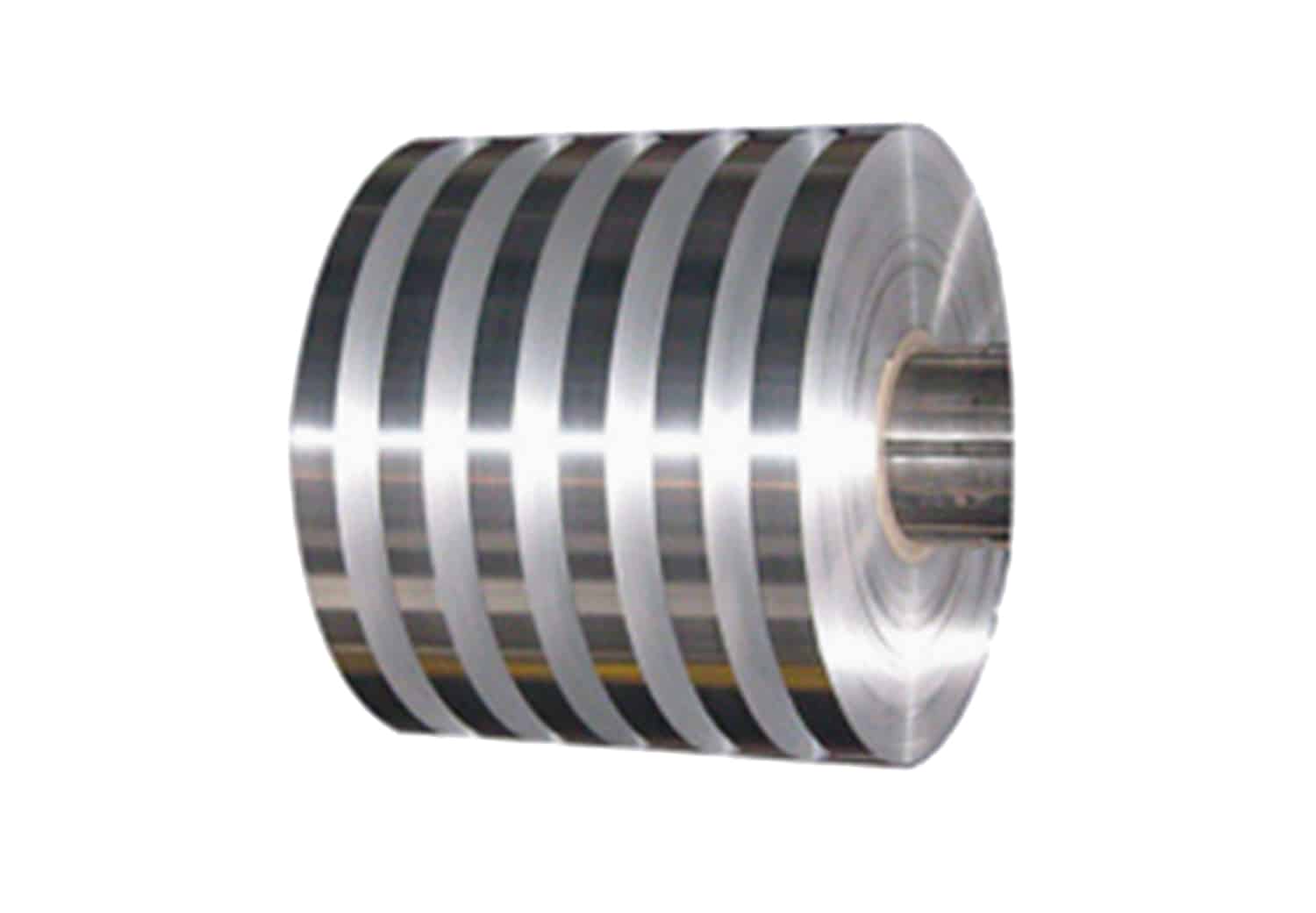

Nowadays, aluminum can, a beverage packaging metal container, has a history of 61 years, with very mature production technology. On a hot day, when we gulp down the beer or carbonated drinks inside, we will notice that the colorful aluminum cans have no processing gaps! Yes, this is due to aluminum cans alloy with excellent stamping performance and ductility, which can well adapt to the high-speed stamping of the can body punch machine, so form a seamless can body! In addition, the excellent ductility also enables the aluminum can lid to be firmly crimped and connected with can body, perfectly sealing the drink! While we were surprised by the perfect characteristics of aluminum alloy for aluminum cans, in practice, the commonly used aluminum alloy coil for cans, with 9 tons weighs and 1.5 meters wide, can produce 750,000 cans ! And This is so efficient !

Specific Aluminum Cans Alloy and Corresponding Application

Currently, there are 1100, 1050, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 5182, 5754 and 5454 aluminum cans alloy grades used for the overall manufacturing of aluminum cans. Among them, the most commonly used are 3104-h19, 5182 h19, and 5052-h19 aluminum cans alloy. The specific corresponding applications are as follows:

3004、3104 Aluminum Coil for Can Body

3004、3104 aluminum alloy coil are the two main alloys used in can body. Among them, 3104 aluminum sheet /coil tensile strength ≥275Mpa, the elongation is up to 20%, and the earing ratio(E)≤4%. Like the 3004 aluminum cans alloy, it belongs to Al-Mn alloy. The addition of main alloy element Mn, not only improves the mechanical properties, but also doesn’t reduce the corrosion resistance of the alloy. The most representative 3104-h19 aluminum coil for can body, has excellent deep impact and strong corrosion resistance. and The inner and outer walls of the aluminum can don’t need pretreatment, the plain aluminum coating/oil can play an excellent oxidation and corrosion resistance. Besides, 3004、3104 aluminum cans alloy all can be well used for thinning and stretching, with low earing ratio, good printing effect, reduced material consumption and reduced batch purchase cost.

5052、5182 Aluminum Cans Alloy for Lids

For beverage aluminum lids with the largest demand, including beer and carbonated beverages such as carbonated acid and alkali, 5182 h19 aluminum alloy was the most used, with common specifications of 0.249*827.89mm, 0.27*946.5mm, 0.22*911mm,etc. And for 5052-h19 aluminum cans alloy, was used for mixed congee and other non-vapor food aluminum lids, with common specifications of 0.25*803mm and 0.25*721.8mm,etc. Most notably, Mingtai Al. has the mature aluminum cans alloy for lids production technology, which can ensure the 5052, 5182 aluminum alloy sheet version of the flat, excellent processing performance, and provide the original warranty!

5182 Aluminum Cans Alloy for Ring Pull of Cans

In addition, 5182 aluminum cans alloy is also the most representative material for ring pull manufacturing. 5182 aluminum sheet belongs to 5 series Al-Mg antirust alloy, and its main composition Mg content can reach 4% ~ 5%. So, 5182 h19 aluminum sheet for ring pull has excellent corrosion resistance and processability, with a common thickness of 0.279–0.406mm. Here, Mingtai Al. introduces advanced grinding equipment to ensure the flatness of the sheet and the thickness tolerance of ± 0.005mm!

Technical Parameters:

| Typical Alloy | Type | Temper | Thickness(mm) | Width(mm) | Length(mm) | Usages |

| 3004 | Sheet/ Plate/ Coil | F,O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H112,H114 | 0.1-500 | 100-2650 | C | Can body (Beer/ beverage/ soda …) |

| 3104 | F,O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H111,H112,H114 | 0.1-500 | 100-2650 | C | Can body (Beer/ beverage/ soda …) | |

| 5052 | F,O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H32,H34,H36,H38,H111,H112,H114 | 0.1-600 | 20-2650 | C | Lids | |

| 5182 | F.O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H32,H34,H36,H38,H111,H112,H114,H116,H321 | 0.15-600 | 20-2650 | C | Lids/ Ring pull of cans |